About

The Company

Learn more about the company, its structure, service, production capacity, logistics, laboratories and more...

Mission

Develop solutions in pigment preparation and thermoplastic additives in accordance with Customers’ requirements.

Vision

Be a domestic reference in preparing pigments and additives for the thermoplastic transformation industry.

Values

Transparency; Commitment; Humility; Common sense.

Potentialities

Logistics

Integrated logistics, from production to product delivery

Stock

Stock more than 350 colors for immediate delivery

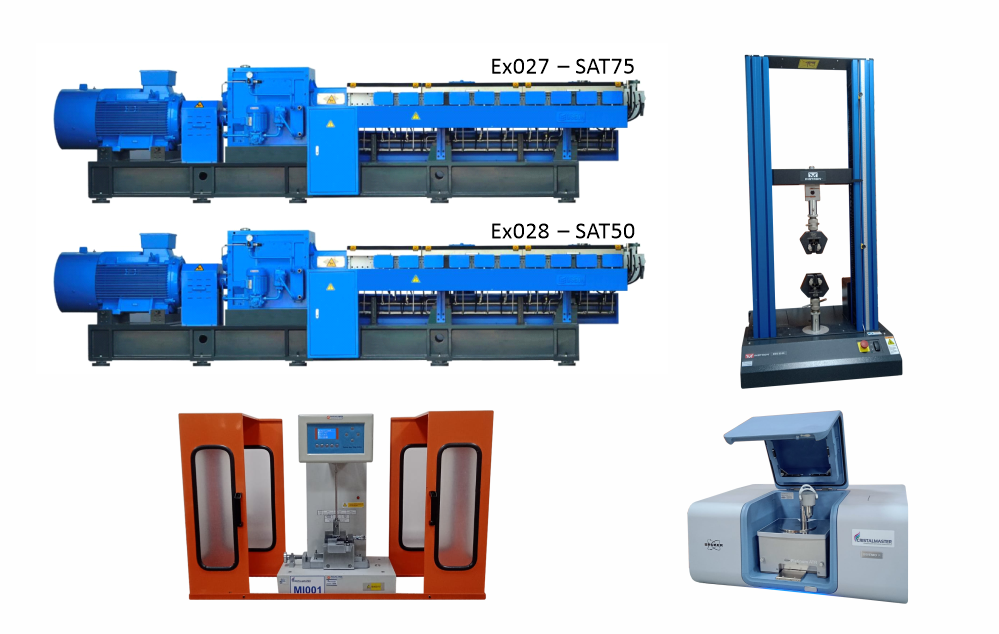

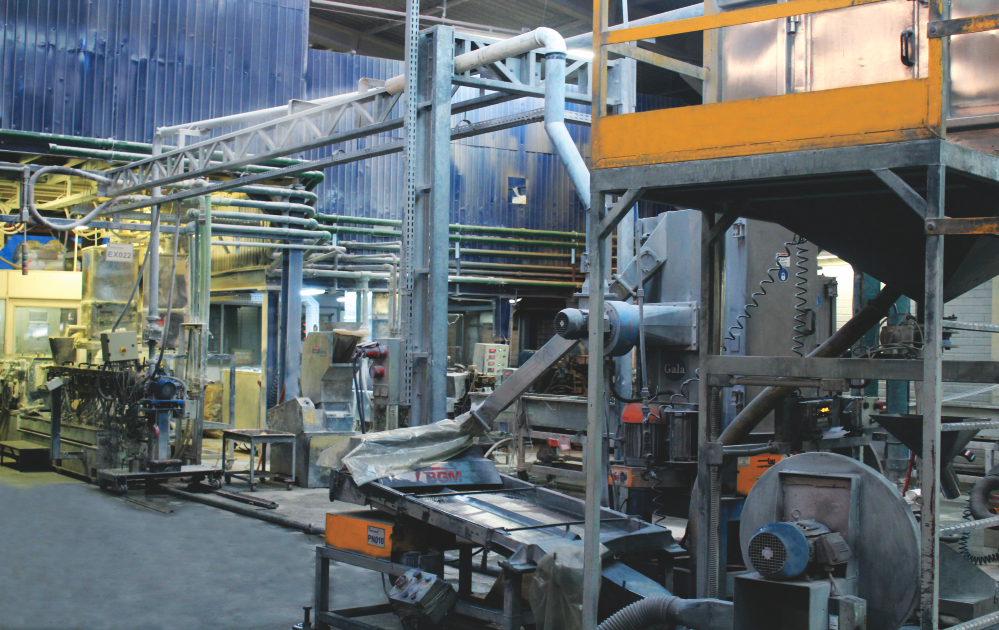

Equipment

State-of-the-art equipment in laboratory analysis processes

Fleet

Own fleet with 26 cargo vehicles and 16 light vehicles

Technical Assistance

By engineers, chemists, technicians and professionals with extensive experience

Certification

Certified quality management system (ISO 9001 standard)

Expertise

Expertise in new product development

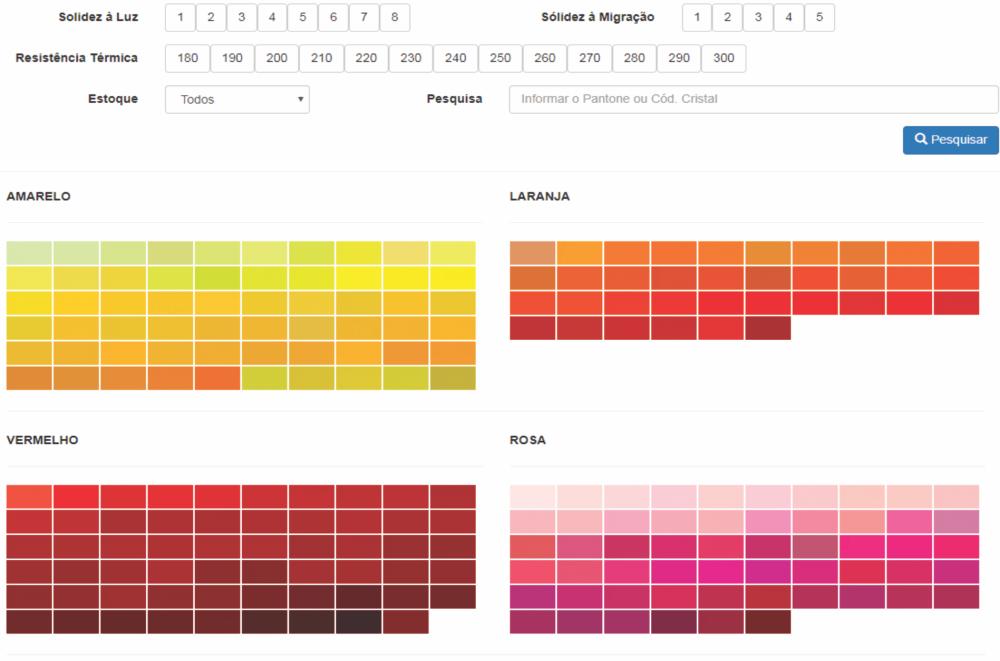

Showcases

Catalog of platelets, films, wires and virtual color catalog

Joinville - Santa Catarina - BR

Headquarters

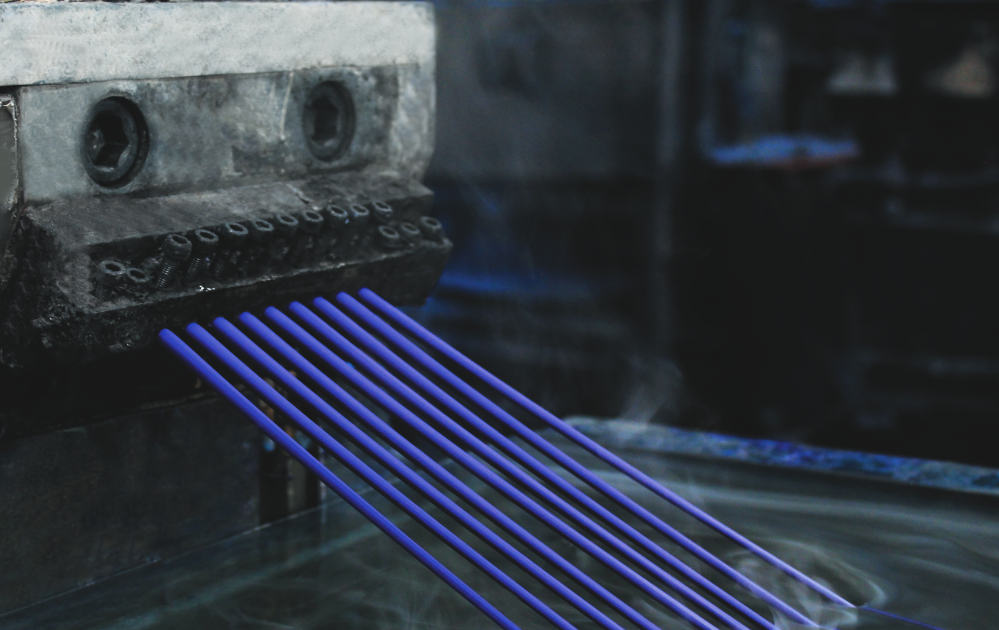

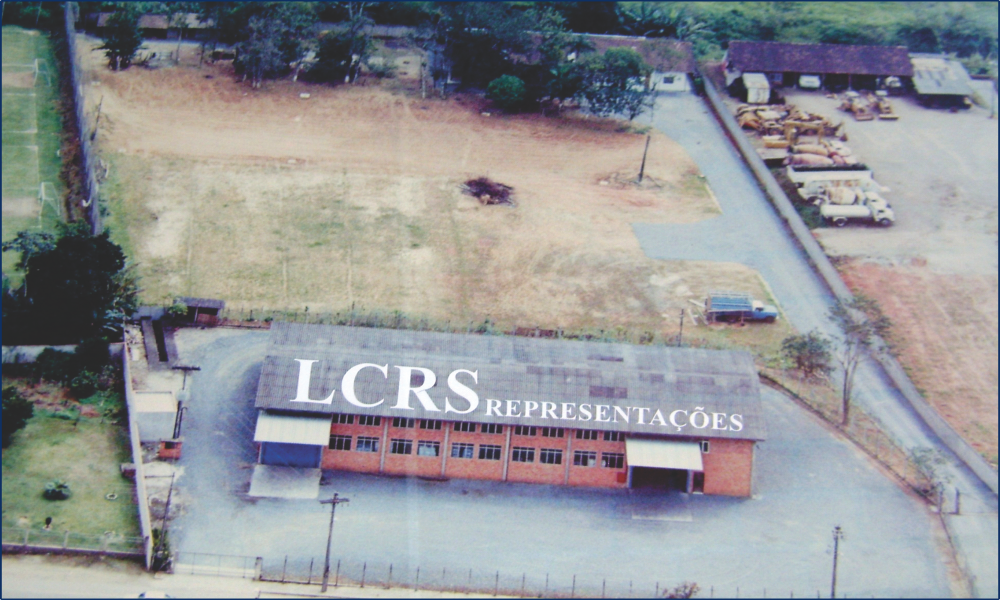

Founded in 2004 in the city of Joinville / SC, Cristal Master provides additive and pigmentation solutions for thermoplastic transformers. In its headquarters it has a modern industrial park, a highly equipped laboratory and a specialized team for the development of new products and quality control of the batches produced. To ensure efficiency and punctuality, it also has its own fleet, making deliveries in the north and south of the country. Cristal Master handles all the domestic territory and Latin America, having a specialized sales team, with fully customized service, seeking to maintain its competitiveness through its commitment to continuous improvement.

RS Branch

Seeking the optimization of logistics and service in the South of the country, in 2012 the first branch of Cristal Master was installed in São Leopoldo/RS, containing inventory to handle the most varied segments of the thermoplastic industry. The deliveries are customized by means of its own fleet.

RS Branch

Seeking the optimization of logistics and service in the South of the country, in 2012 the first branch of Cristal Master was installed in São Leopoldo/RS, containing inventory to handle the most varied segments of the thermoplastic industry. The deliveries are customized by means of its own fleet.

PE Branch

Prioritizing quality in service and swiftness in deliveries in the northeastern region of Brazil, the unit installed since 2013 in Jaboatão dos Guararapes/PE, has inventory to handle the most varied types of thermoplastic transformers in the region.

PE Branch

Prioritizing quality in service and swiftness in deliveries in the northeastern region of Brazil, the unit installed since 2013 in Jaboatão dos Guararapes/PE, has inventory to handle the most varied types of thermoplastic transformers in the region.

SP Branch

Focusing upon the quality of service and optimizing logistics for the Brazilian central west and southeastern region, the installations of the branch of Itupeva/SP have been operating since 2014, to handle all the segments of the thermoplastic industry. It has inventory available of coloring masterbatches and additives, besides its own fleet for deliveries in the region of São Paulo.

SP Branch

Focusing upon the quality of service and optimizing logistics for the Brazilian central west and southeastern region, the installations of the branch of Itupeva/SP have been operating since 2014, to handle all the segments of the thermoplastic industry. It has inventory available of coloring masterbatches and additives, besides its own fleet for deliveries in the region of São Paulo.

Timeline

History

-

Acquisitions / Growth Structure

- Production Capacity: 55,000 tons/year - 6 Reach Trucks and 1 Electric Forklift - 2 Trucks, 2 Sprinters and 2 Polos - New administrative facilities (commercial, supply, finance, reception and management) - 3 new Extruders (Ex034/EX035/EX036) - Roadway for safe cargo access - Expansion of service in the international market (South and Central America).

-

Acquisitions / Growth Structure

New Guardhouse – Asphalt Paving of 2,300 m2 – Expansion of Electrical Infrastructure – Construction of a New Pavilion with 5,000 m2 of Warehouse with 04 Docks for Loading and Unloading – Installation of Line for Internal Trimming Recycling (EX033) – Installation of Water Cutting for Line EX018 (CA007) – Start of 6X2 Relay – Second Truck for SP Branch – Replacement of 01 Truck for RS Branch – 01 Horse-Trailer with 4th Axle Trailer (37 Tons) – 01 Truck for Head Office – Replacement of 01 MB Atego Truck – 02 Benchtop Spectrophotometers – 01 Dehumidifier – Acquisition of Land and Warehouse Next Door (Land: 5,000 m2 and Warehouse: 900 m2)

-

Acquisitions / Growth Structure

Road Scale – Landfill for New Pavilion – Fire Prevention – Pallet Rack – Expansion of Support Sectors such as HR, Restaurant and Laboratory – 02 Twin Screw Extruders EX031 and EX032 – 02 New Granulators (Primotécnica and Sagec) – 10 VW Polo Vehicles – 01 MB Sprinter – Second Filter Test – 01 Xenotest.

-

Expansion / Acquisitions

- Laboratory Expansion - Auditorium expansion - Refectory expansion - Expansion of Financial ADM. - Two Volvo VM Trucks; - A Mechanical Horse + Cart with load capacity for 30 Ton; - A light vehicle (Yaris); - Plastic Brazil Exhibition.

-

Acquisitions / Structural Growth

- Expansion of the stock area and yard; - Film extruder; - Two forklifts; - Injection machine; - Multifilament machine; - A Sprinter Van; - Two Volvo VM trucks.

-

Acquisitions

- Injector for the Laboratory; - FTIR; - Machine for impact testing; - Traction/flexion testing machine; - COF; - Stereomicroscope; - X-Rite software; - Two 50mm double screw extruders; - Total plant 19 extruders; - Capacity for 32 m

-

Structural / Productive Growth

- Land of 10,000m² - New refractory Muffle. - New Calandra. - Extruder 75mm double screw 17 in total - Production capacity of 30 thousand ton/year. - Growth of 18%.

-

Productive Growth

- Installation of a 75mm double screw extruder. - 16 extruders in total. - Production capacity of 28 thousand tons/year.

-

Productive Growth

- Installation of a twin screw extruder - 15 in total. - Production capacity of 18 thousand tons/year. - Growth of 22%.

-

Implementation of Virtual Catalog / Productive Growth

- Installation of a twin screw extruder - 14 in total. - Production capacity of 12,000 ton/year. - Created the virtual color catalog. - 10% growth.

-

Productive Growth

- Installation of twin screw extruder 13 in total. - Production capacity of 11,000 ton/year.

-

Third Branch / Productive Growth

- SP branch installed. - Installation of three twin screw extruders - 12 in total. - Production capacity of 10,500 ton/year. - Growth of 29%.

-

Second Branch / Fleet Acquisition

- Installed PE branch. - Own fleet. - Installation of two twin screw extruders 9 in total. - Production capacity of 8,500 ton/year. - Growth of 39%.

-

First Branch / Productive Growth

- RS branch installed. - Installation of a twin screw extruder - 7 in total. - Production capacity of 6,000 ton/year. - 25% growth.

-

Solo career

- Acquired shares of the other three partners, beginning of a solo career. - Industrial park with a total of 2 single screw extruders and 6 twin screw extruders. - Production capacity of 5,000 ton/year.

-

Certification / Marketing

- ISO 9001 certification. - Presence confirmed in the main fairs of the sector. - 25% growth.

-

Technical / Productive Structural Growth

- Improvements in the Laboratory. - Production capacity of 4,000 ton/year. - Growth of 29%.

-

Productive/Structural Growth

- It has 3 single screw extruders and 4 twin screw extruders. - Production capacity of 3,200 ton/year. - Growth of 32%.

-

Structuring / Computerization

- ERP (Integrated Management System) is implemented. - Production capacity of 2,800 ton/year. - Growth of 73%.

-

Productive Growth

- Production capacity of 1,500 ton/year. - Growth of 87%.

-

Structure

- It has 3 single screw extruders and 2 double screw extruders. - Production capacity of 750 ton/year.

-

Foundation

Mr. Luiz and 3 other partners inaugurate Cristal Master.